i am a cheap bastard, and as such i have no intention of bothering with an external WG anytime soon. so in the interest of fattening my own head, i thought i'd bring this up for discussion.

so i was trying to work out a simple EBC setup that would be cheap and effective. this is what's on the car right now:

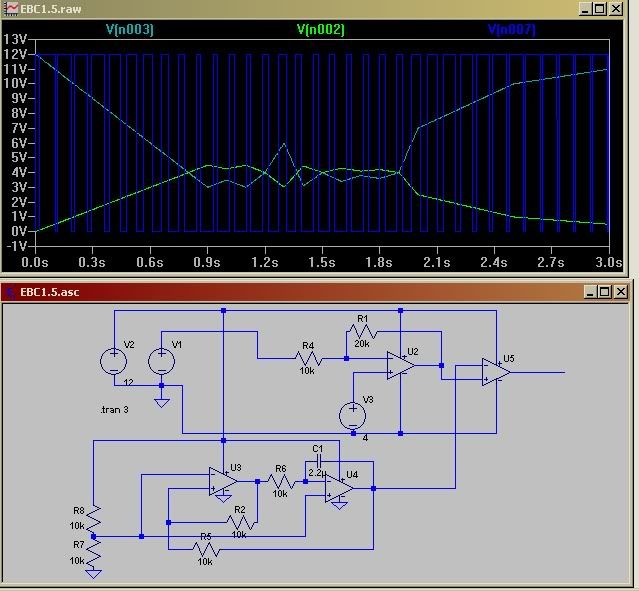

(red trace is simulated MAP voltage, green is output of amplifier to pressure switch/comparator)

the idea is to use an amp on the MAP sensor line and an RC filter on the output, so that it amplifies the MAP signal with respect to how quickly pressure is changing. the faster pressure rises, the higher it pulls the map signal. the faster it falls, the lower it pulls the signal. the intent was to allow the solenoid controlling the wastegate pressure to be able to anticipate the WG's position to avoid spiking.

it works, but it's meh. it definitely works better than the grainger valve MBC i was using before.

so now i've got this on the drawing board:

this one should work better. the MAP signal is input to a differential amplifier. the output of the amplifier is inverse to where the MAP voltage is with respect to the reference (boost level) set point. the more OVER the boost set point, the lower the amp drives the output.

the bottom of the circuit is a 12Hz triangle wave oscillator. the output of this is sent to one comparator input, with the amp output sent to the other input. so essentially, when the MAP goes over the set point, the output of the circuit results in more duty cycle to the drive solenoid (normally closed, used as a bleed. more DC= higher boost). like the other circuit, this also is a closed-loop system, but with finer control. the nature of the amplifier in the first part of the circuit will drive the solenoid with whatever duty cycle it takes to get the MAP to equal the reference voltage. it's like a closed-loop bleed type MBC, really.

there are two other parts i need to add to the circuit:

1. an initial level for the controller to start pulsing the solenoid. it would just be a pressure switch that holds the solenoid at 100% duty while the turbo is spooling, and at, say, 3 or 4 psi before the desired boost level, lets the controller take over the solenoid.

2. mostly just an optional thing, but another pressure switch that holds the solenoid closed (boost at wastegate pressure) until the coolant temp is above a specified level. kind of an "i'm a cold engine, don't beat on me yet" failsafe. i probably won't bother with this one.

my concerns are also for once i want to go above 22psi or so and the WG starts to blow open. i've thought of using the same controller as the second one above, but change how it runs the wastegate.

instead of manifold pressure being fed to the WG actuator, use a lightweight, noncorrosive fluid (coolant, maybe) and a small windshield washer pump capable of 40+psi. bump the frequency of the oscillator up to about 2kHz and use the controller to drive the pump to control wastegate position. that way, i can use a WG with an extremely stiff spring, and still retain control of any boost pressure i want.

i had looked at similar methods using PS fluid or even engine oil pressure to actuate the WG, with something like toyota's VVT oil control valve to control WG position.

anyone have any other ideas?

Author

Topic: better internal wastegate control for high boost. discuss? (Read 22355 times)

Author

Topic: better internal wastegate control for high boost. discuss? (Read 22355 times)